How It’s Made: A Detailed Manufacturing Process For A Smartphone

In today’s world, smartphones have become indispensable companions for many people. This is due to their portability and ease of use – making them essential assets in our daily lives.

The manufacturing process behind a smartphone is one that can be quite intricate, requiring the utilization of numerous tools and processes to create the finished product. To get an in-depth understanding of how these devices come together, let’s take a look at how they’re put together.

Starting With Prototypes

Before a company can even begin conceiving of the creation of their new device, it will require some preliminary research. This entails creating a prototype from scratch – an act that is not only inexpensive; but also expedient and time-saving.

A prototype is an early sample of a product given for evaluation or testing purposes. It’s meant to be simple – devoid of features such as branding or aesthetic details – so as not to impede on its functionality.

Typically, companies may utilize one of two approaches when it comes to building prototypes: either through injection molding processes or computer-aided design software. Here are what those approaches entail:

Using injection molding technology, smartphone makers can craft unique prototypes of their desired design at a fraction of the cost compared with conventional methods.

Once they’ve finalized their specifications, these intricate models can be swiftly produced in bulk and then sold off as a means of gauging customer reactions before finalizing any plans for mass production later on! As you might expect, this process typically requires quite some effort before reaching fruition – however; should prove invaluable for identifying any potential pitfalls along the way.

Configuring Software

Once the prototype has been successfully created, it’s time to configure the software that will run the device. Smartphone companies will develop custom software that can be tailored to their specific needs.

This software will take into account the various hardware components such as the processor, memory, display, and other components. The software will be designed to integrate with these components in order to create an effective and efficient device.

A typical development process typically starts with the creation of a user interface; which should be designed with the general consumer in mind. During this phase, design elements such as fonts, colors, and layout will be finalized.

Once the interface has been established, the development team will begin coding the software and writing the necessary programs and applications to make the device function as desired.

This process typically requires a great deal of testing and debugging to ensure that all the components are working in harmony and that the device is functioning as intended.

Building The Hardware

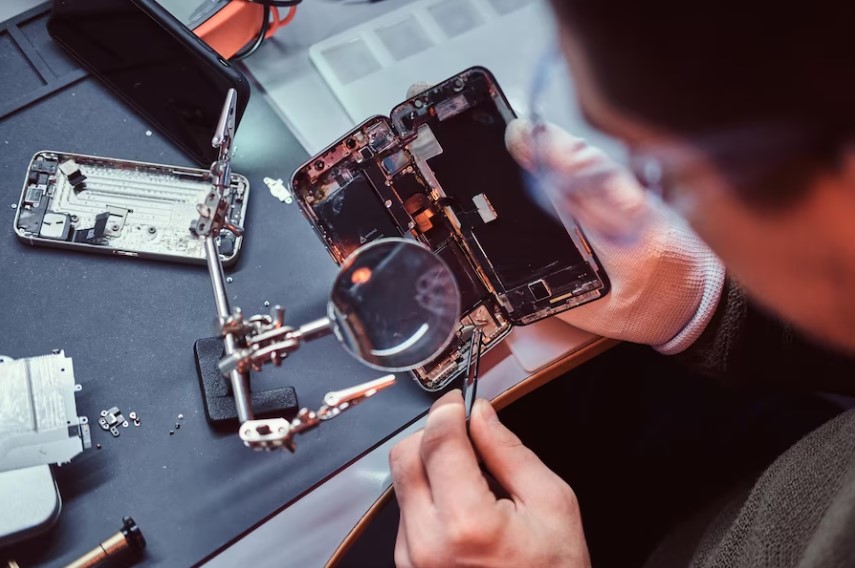

The hardware for smartphones is typically made up of small parts and components, which are too small for traditional assembly techniques. This is where microdispensing in the microliter range comes in. Microdispensing involves using tiny needles to precisely deposit droplets of adhesive on the components, bonding them together.

The adhesive is then cured using ultraviolet light or heat. This process is highly accurate and is ideal for assembling intricate parts with tight tolerances. It also ensures that the components are securely attached and less likely to become loose or detached. Microdispensing can be used to attach components such as cameras and sensors, which are often too delicate for traditional assembly techniques.

Testing Functionality

Once the prototype has been created and the hardware and software have been configured, it’s time to test the functionality of the device. Testing the device involves running it through a series of rigorous tests to make sure that it performs as expected. This includes testing the hardware components, the software, and the overall user experience.

Hardware testing typically involves making sure that the device can stand up to the wear and tear it may experience in the real world. This involves putting the device through a series of stress tests to make sure that it can withstand extreme temperatures, pressure, and shock. Tests are conducted to ensure that the various components are functioning correctly, such as the camera, sensors, and display.

Testing the software includes making sure that the device is properly integrated with the software. This includes making sure that the user interface is intuitive and the device is responsive to user input. Additionally, tests are conducted to ensure that the device is running the correct version of the software, that the software is bug-free, and that the device is secure from potential cyber threats.

Once the device passes these tests, it is ready for final evaluation. This typically involves having an expert panel evaluate the device and provide feedback. This feedback can then be used to refine the device and make sure that it meets customer expectations. Once the device has been optimized, it can be released to the public.

The smartphone manufacturing process is a highly specialized undertaking. From the moment a raw material is created to its attainment as a completed product, each step must be followed precisely in order for the device to be completely functional.

Read Also:

- Financial Tips For Starting A Business

- How You Can Boost Your Business Bottom Line

- 4 Types of Analytics Your Business Should Track